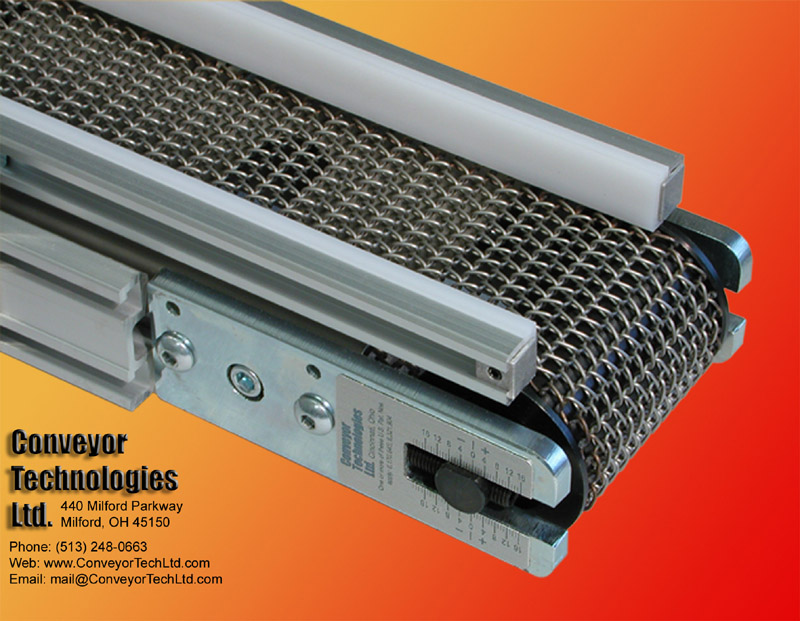

New Conveyor

Technologies low

profile stainless steel wire mesh belt conveyor can really take the

heat -- in excess of 1000°F

Easy to clean and immune to chemical reaction, wire mesh belt is ideal

for diverse applications from metalworking to food and cleanroom medical

April

2004 —Conveyor Technologies' newest development in modular low-profile

conveyors features a stainless steel wire mesh belt with exceptional

thermal and chemical resistance, combined with a 60% "open flow

area." Capable of

handling part contact temperatures above 1000°F, the belt construction

affords both lateral and longitudinal flow of air or liquids throughout

the entire belt, making it ideal for heating, cooling, wash down or

flush-and-drain applications.

The conveyor's open belt construction enables easy and

thorough cleaning and inspection. Odor and flavor absorption are

eliminated because the wire mesh belt is virtually immune to chemical

reaction. The conveyor is highly suitable for clean room and food,

pharmaceutical and medical equipment applications because there are no

belt fibers or plastic abrasion particles to cause contamination.

"The contoured supporting surface of the wire mesh belt

affords only minimal contact with the product, making it perfect for

handling many food and drug products, or for draining parts that are

saturated with coolant or other fluids, which can drain laterally through

the belt without contaminating the return side, " said Charles

Mitchell, president of Conveyor Technologies.

The wire mesh belt conveyor is available in widths from

2" to 12". All product supporting surfaces are round and formed

in a single-piece lateral spiral, which imparts high lateral stiffness to

the belt and allows openings in the frame surface for air or fluid flow.

The belt allows easy replacement of modular sections if damaged.

Internal automatic spray wash can be applied providing 100% belt

coverage on the return side. This unobstructed reverse flush through the

belt provides the most efficient belt cleansing.

Available guide rails include UHMW or high temperature UHMW

that can withstand part temperatures up to 500°F;

stainless steel to handle wash down or part temperatures to 1000°F;

optional anodized aluminum Dual “T” Slot Rails are available for

attaching accessories.

Both the belt and frame are stainless steel, eliminating the

need to compensate for the thermal expansion differential common with

plastic belting. A stainless-steel positive-traction, centering-drive

pulley eliminates slippage and tracking problems.

Belt

life is extended by a flanged, bearing-mounted idler, which reduces

sprocket engagement wear by 50%. As in all Conveyor Technologies

low-profile conveyors, bearings and drives are sealed for life and require

no further lubrication.

The

stainless steel wire mesh belt conveyor joins the Conveyor Technologies

line of low-profile conveyors, engineered for flexible, high up-time

production, which have proven ideal for automation of work cells,

packaging machines, automation, assembly and similar operations. A broad

selection of modular low-profile conveyor designs enables close

application-tailoring at standard unit economies. Line choices include

end-drive, center-drive, cleated, magnetic, vacuum, high temperature, high

speed, self tracking, and AccuMove precision indexing conveyors.

For

additional information, contact Conveyor Technologies Ltd. Tel:

513-248-0663. Fax:

513-248-0685. E: sales@conveyortechltd.com

Internet: www.conveyortechltd.com

END

Click for

Literature